Peristaltic & hose pumps principle

Peristaltic pumps are a form of positive displacement pump, which can be used for pumping a wide variety of fluids.

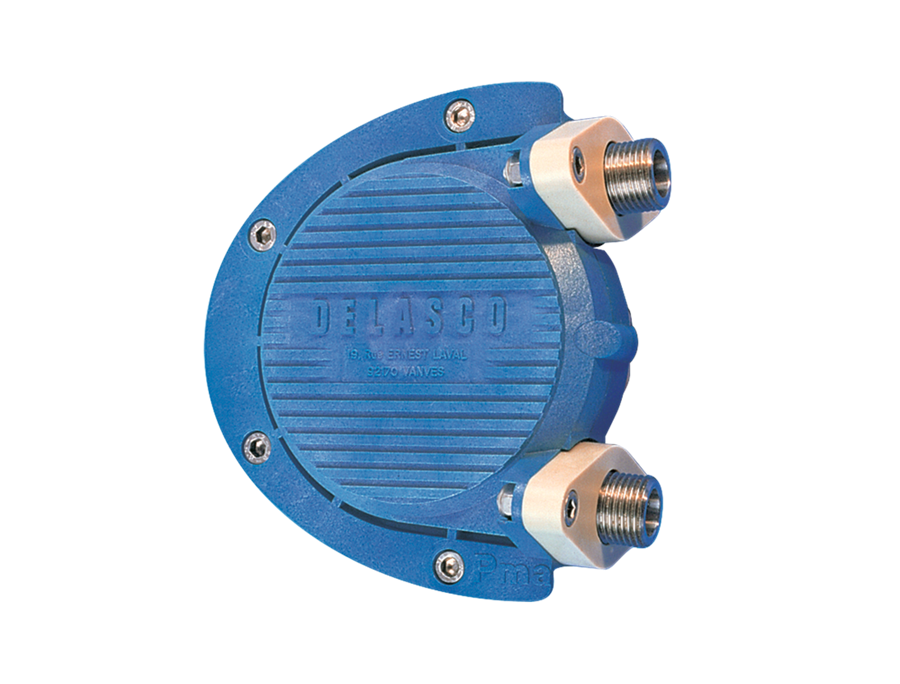

Our industrial pumps use the peristaltic principle, whereby a the deformation and compression of a soft elastomer hose allows fluid to be passed through the system.

We have a wide range of industrial hose pumps, covering a variety of applications. To offer you flexibility, our selection includes high pressure and low pressure pumps. You can also choose between different flow rates, from 200l/h to 65m3/h.

Technical hose pumps advantages

- The hose is the only part of the pump which gets worn, resulting in reduced maintenance costs

- Additionally, the lack of valves and seals means less upkeep is needed

- Self-priming design

- The hose pump can handle corrosive and abrasive products such as slurries and viscous materials

- They can also be used with delicate fluids

- It is also suitable for use with dry matter and solid particles

- Peristaltic pumps reduce backflow

- Dry running is possible without damage occurring