Many industrial processes for the transfer or dosing of fluids are about products like effluent, sludge or other waste type often loaded with solids or semi-solids. In order for the pumping of such fluids to remain possible, it is important that the installations used have grinding equipment capable of reducing the solids to fine particles in order to protect the downstream equipment without slowing down or interrupting the entire process.

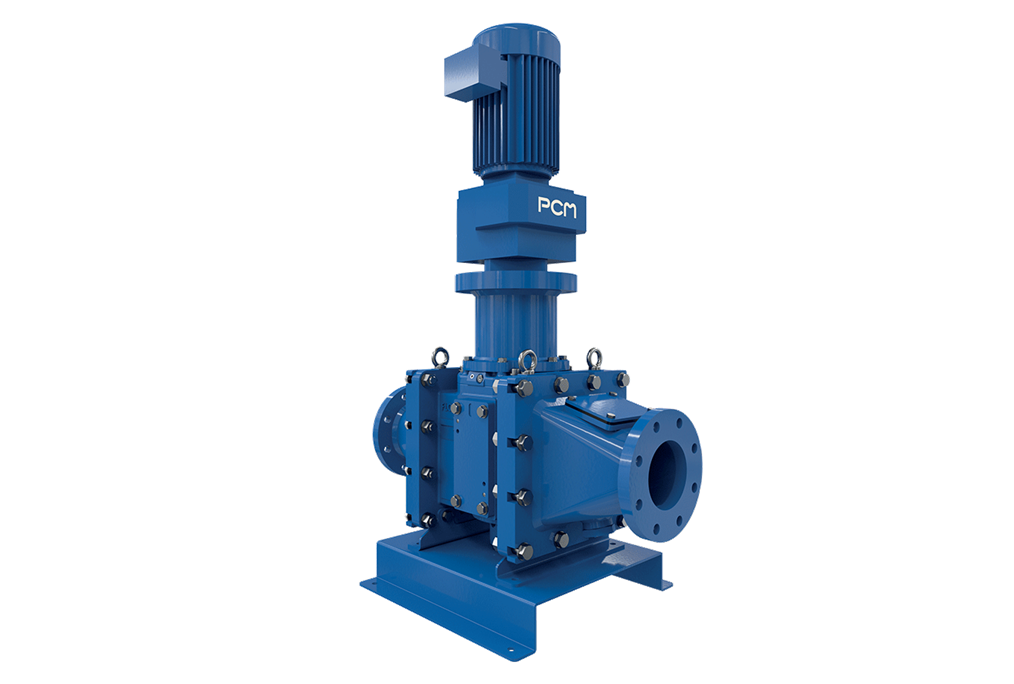

PCM offers technologies that are well suited to different types of waste to be grinded and offers a macerator for filamentous string-type materials and a grinder for solid wood, plastic or pebble material.