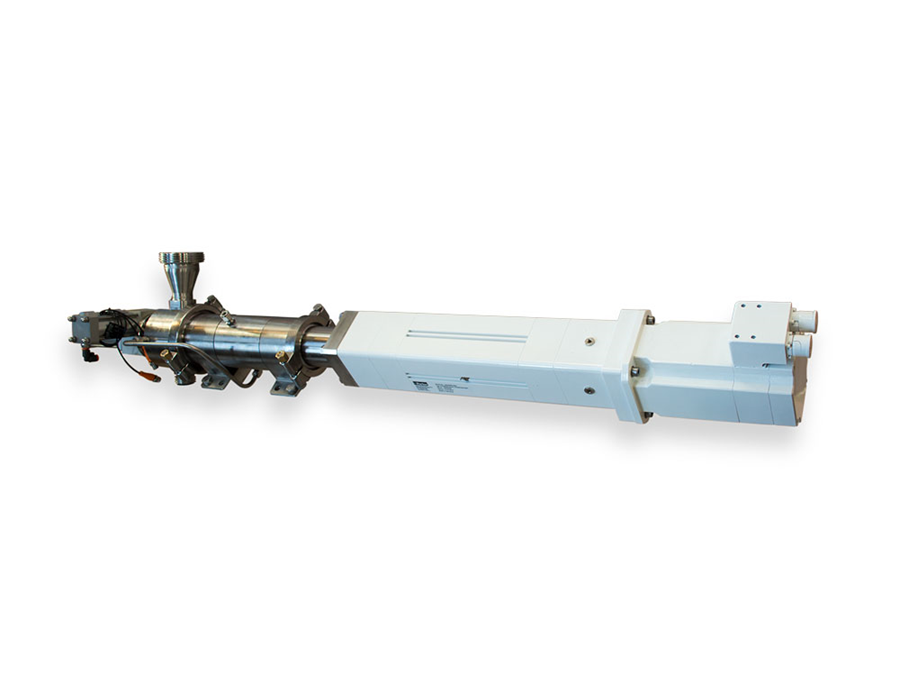

Dosing Pumps

The PCM dosing pumps are designed to minimize losses while offering maximum flexibility. The precision and the flexibility are the keys to a perfect dosing.

PCM provides a wide range of solutions for the dosing of your most valuable ingredients. These products offer many advantages:

- Integrated efficiency: the PCM dosing systems ensure optimum consumption of your ingredients and are fully cleanable in place.

- Total flexibility

- Reduced operating costs

- Respect of pumped product

- Easy cleaning