INDUSTRIAL MIXERS

Our industrial food mixers produce a uniform finished or semi-finished product, making it ideal for any process. They are suitable for use with liquids, and work particularly well with fragile ingredients that contain pieces, or that are likely to swell during the mixing process.

We only use the highest quality food grade materials to build our mixers, and all are designed to 3A standards, to ensure clean, sterile and low-risk operation. And as there’s no need for an open air mixing tank, the threat of product contamination is completely eliminated.

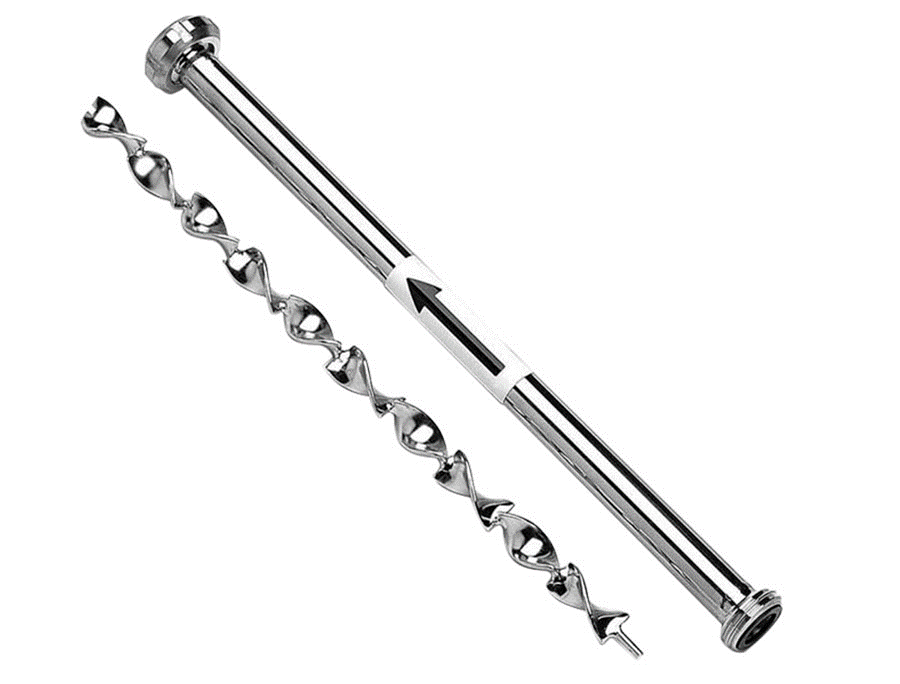

In-line mixing can easily be integrated into continuous processing lines, unlike batch mixing, which is performed in batching tanks for discontinuous processes. Because in-line mixing uses progressing contact rather than beating, you can ensure a uniform mix, whatever your ingredients.

PCM has a range of mixers to choose from, including Dosymix™ and Dostam in-line dynamic and static mixers.

Applications

- Dairy products

- Meat and fish

- Pet food-products

- Sugar

- Convenience foods

- Industries

Advantages of the continuous process

- Just in time product completion

- Fast mixing, ensuring timely completion of your products

- Reduced waste product

- Saves space, as the mixer is smaller

- Ingredients are evenly mixed

- Can easily respond to last-minute changes to recipes

- Easier inventory management

- Minimisation of investments

- Designed to 3A standards, they are easy to clean, maintain and sterilise

- Risk of product contamination is eliminated