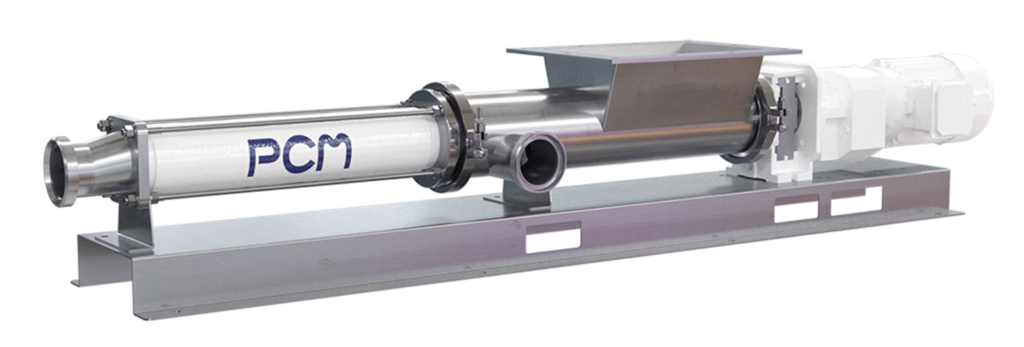

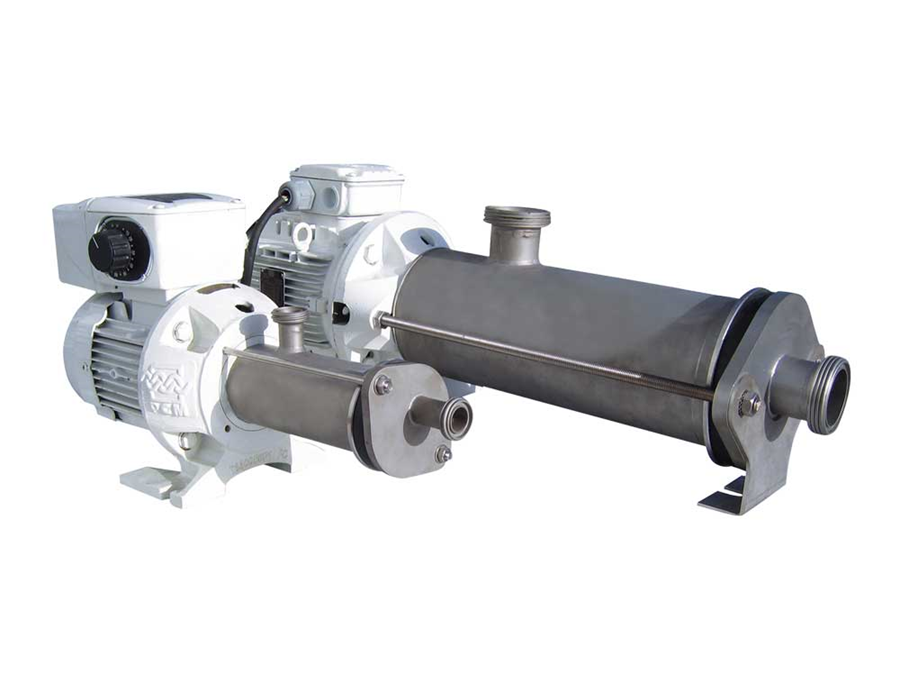

PCM Hycare™ Sanitary Progressing Cavity Pump

PCM HyCare™ is the world’s gentlest, most hygienic food sanitary pump. It’s been especially designed for food applications, featuring a patented body design developed using advanced computational fluid dynamics. This progressing cavity pump will treat your ingredients, food safety requirements and budget with the care and respect they deserve.

HyCare™ uses patented Moineau technology to protect the quality and texture of pumped products. With these PCPs, 67% of the product texture is protected – a huge amount compared to Lobes pumps and Bi-Wing pumps, which only protect 15%.

HyCare™ is the cleanest food grade pump available on the market. 3-A or EHEDG certification guarantees optimum hygiene for both the process, and the final product.

Its Duraflex flexible shaft means it’s the shortest food grade pump available, ensuring loss at the end of the production process is kept to an absolute minimum.

Avantages of PCM HyCare™ PCP

Cleanable

- With an internal body designed using Computational Fluid Dynamics, cleaning has been improved by 30%

Simplified maintenance

- As there’s no joint, no maintenance is required on the flexible shaft

- No adjustment on the mechanical seal in a cartridge

- Can be quickly and easily disassembled, thanks to the two-part body and shafting assembly system

Reliable in every situation

- The Duraflex flexible shaft is made from hard-wearing titanium – more dependable than open joints

- Our patented stator anti-rotation system ensures safe operation, in the events of high pressure or temperature

Product respect

- With our food grade pump, 67% of the product texture is protected, a huge amount in comparison to Lobe pumps and Bi-wing pumps, which protect just 15%

Performances of PCM HyCare™ PCP

How well do our food grade pumps perform?

- Pressure: 16 bars

- Flow rate: from 20 l/h to 50 m3/h

- Particle size up to 32mm