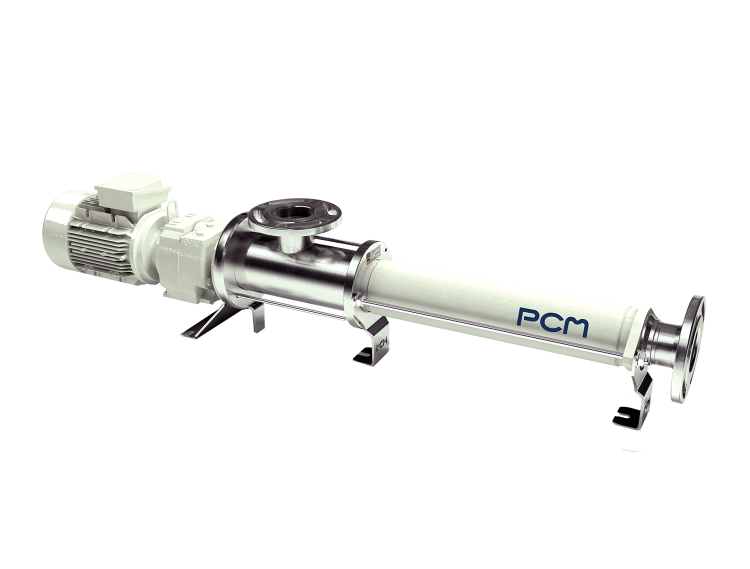

Cast iron progressing cavity pump- EcoMoinea ™ M

PCM Ecomoineau™ M is the most compact progressing cavity pump (PCP) available on the market today. Its revolutionary design combines the legendary Moineau™ technology to performance and reliability of PCM PCP technology with a highly modular, eco-friendly design.

The EcoMoineau™ M is available in different versions:

- Fixed stator

- Floating stator

- Also available with hopper

Characteristics

- Multiple flanges

- Standard hand holes

- Revolutionary joint

ATEX certification

Advantages

Simplified servicing

At first glance, the Ecomoineau™ M pump may look like an ordinary PCP, but a closer look reveals a multitude of design features that make installation, operation and maintenance easier than ever before. For example:

- The seal can be changed by simply disconnecting the drive.

- The shaft line (rotor, coupling rod, driving shaft) can be removed without disconnecting the pipes.

- The integrated version comes with a smaller diameter, self-positioning mechanical seal.

Reduced space requirements

Because the EcoMoineau™ M pump is more compact than comparable progressing cavity pumps, it requires less space for installation and servicing, which speeds up maintenance, reduces civil engineering costs and eases integration systems. Most progressing cavity pumps require clearance of nearly a stator length maintenance operation; the EcoMoineau™ M pump requires just 100 mm. It can be installed in smaller premises and can be hoisted using lighter lifting gear.

Reduced life cycle costs

The EcoMoineau™M pumps comply with the European Energy-using Products (EuP) directive. Lighter by 38% (less raw materials) and more economical (energy consumption reduced by 10%) than the previous generation of Moineau pumps, they require less energy to manufacture, transport and operate.

Performances

- Maximum flow rate: from 0.3 m3/h to 180 m3/h /from 1.32 à 792.5 US GPM

- Maximum pressure: 24 bar / 350 psi

- Maximum temperature: 120°c /250°F

- Particle size: 40 mm / 1,57 inches